Products

Online condition monitoring system

iSee Online Condition Monitoring System

iSee Online Condition Monitoring System

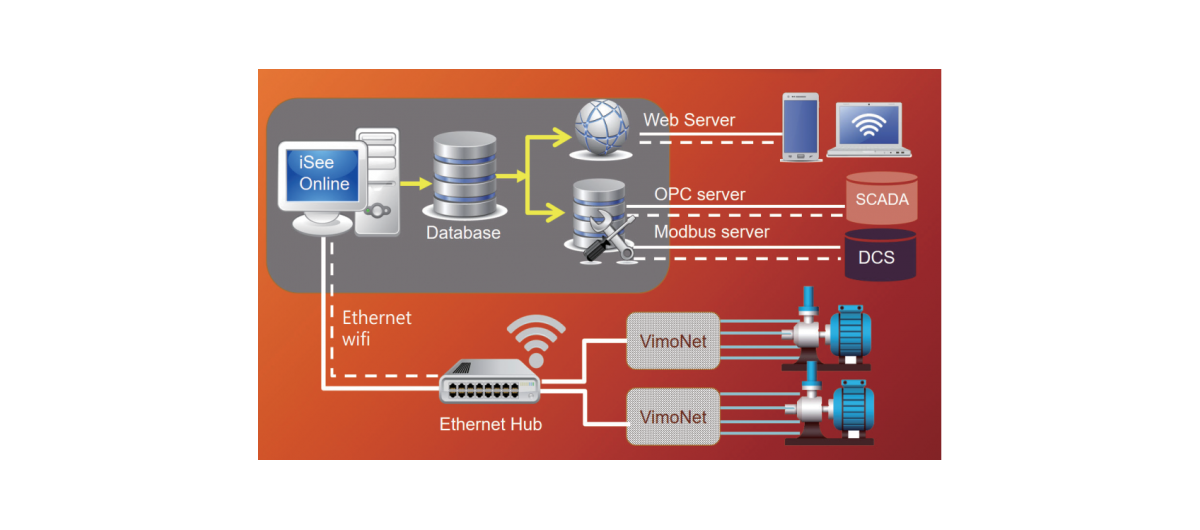

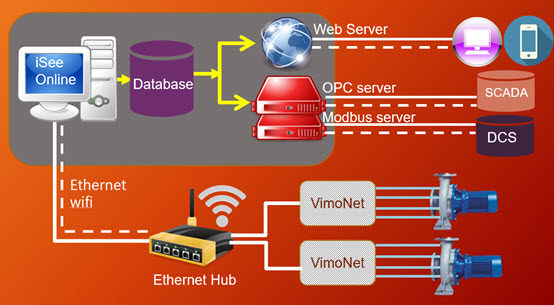

The iSee Online Condition Monitoring System adopts the concepts and technology of an “industry 4.0 smart factory” with continuous vibration monitoring of critical machines to prevent costly unscheduled shutdowns.iSee Online Condition Monitoring System manages the installed VimoNet Data Acquisition Modules hardware by collecting important parameters of rotating machines through cable, optical-fiber or wireless network. It provides instantaneous information about your machines’ health. Browser-viewable data can be viewed by an unlimited number of users on Android, iOS, or a PC. Optionally, OPC and Modbus servers make it possible to share archive data to an enterprise database or DCS system for further data processing/ applications.

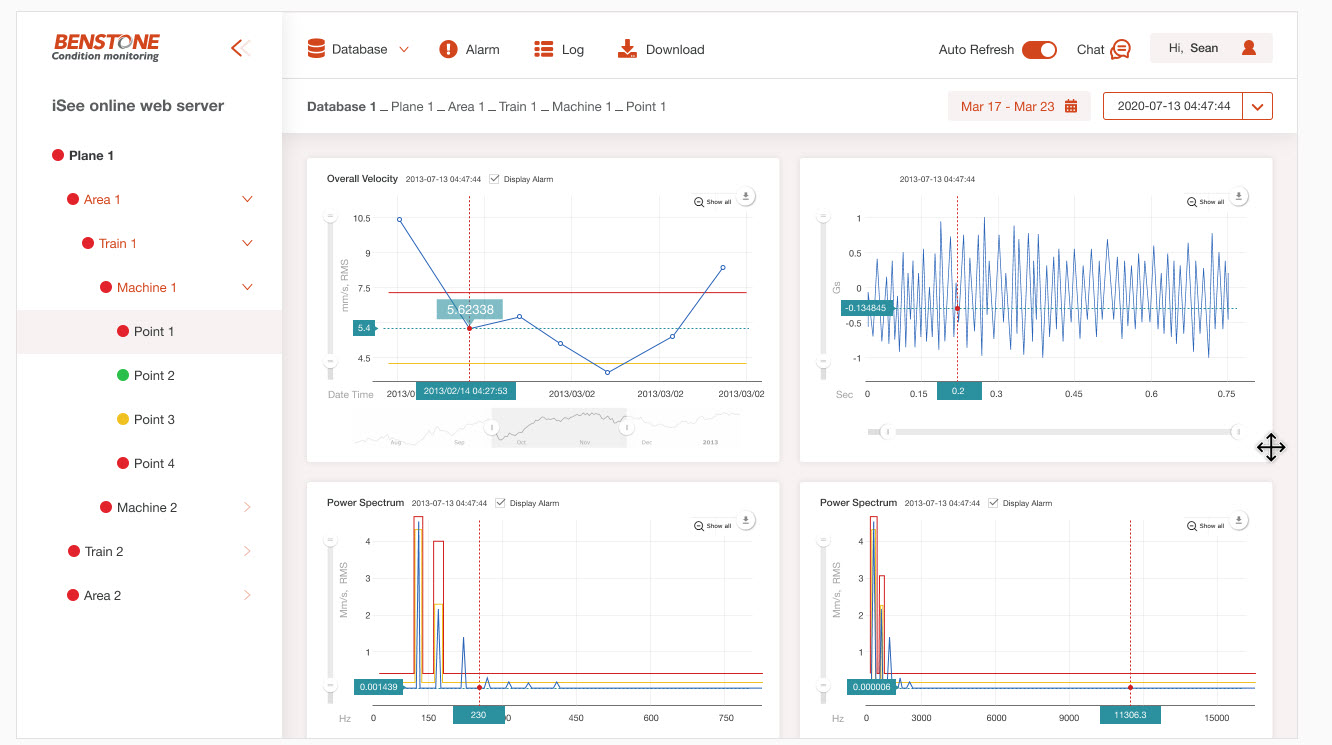

iSee Online Condition Monitoring Software

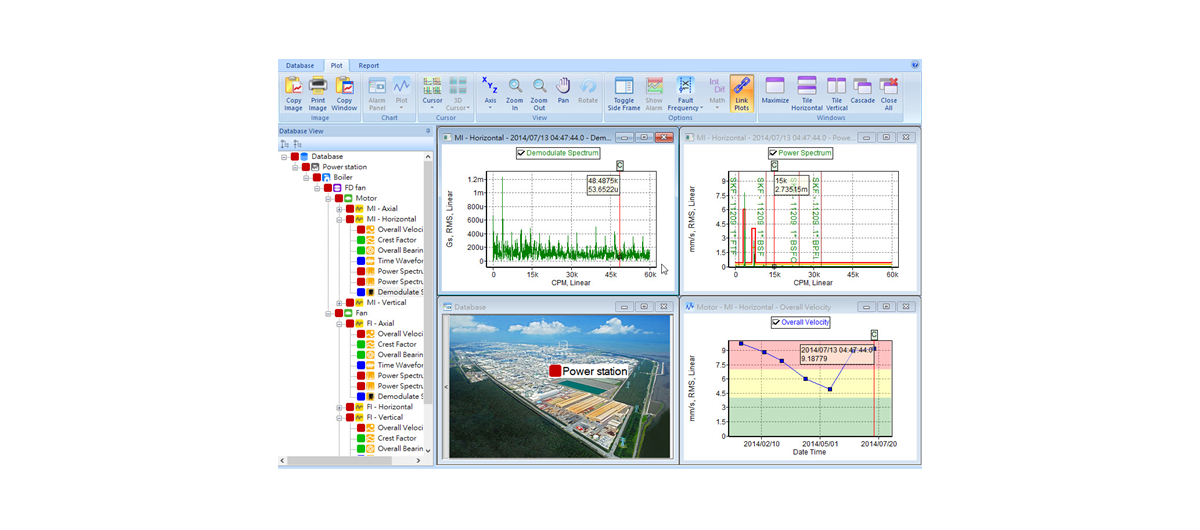

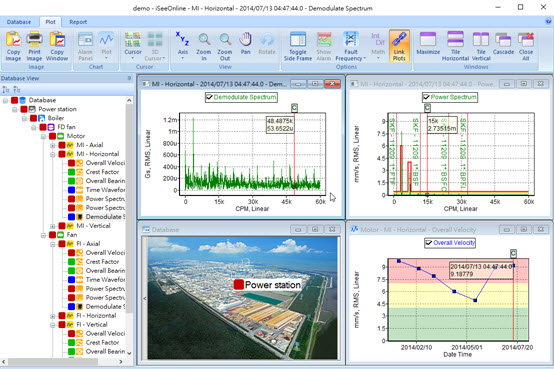

iSee Online Condition Monitoring Software is easy to use, yet powerful. Easily build a database of your machines and monitored parameters, know the alarm status, and conduct fault analysis when necessary. iSee Online Condition Monitoring Software consists of 3 modes: Database Mode, Plot Mode, and Report Mode.

Database Mode

In Database Mode, you can• Create a database for the machines you are going to monitor

• Set up the monitored parameters for each point

• Assign the points to corresponding remote VimoNet Data Acquisition Modules

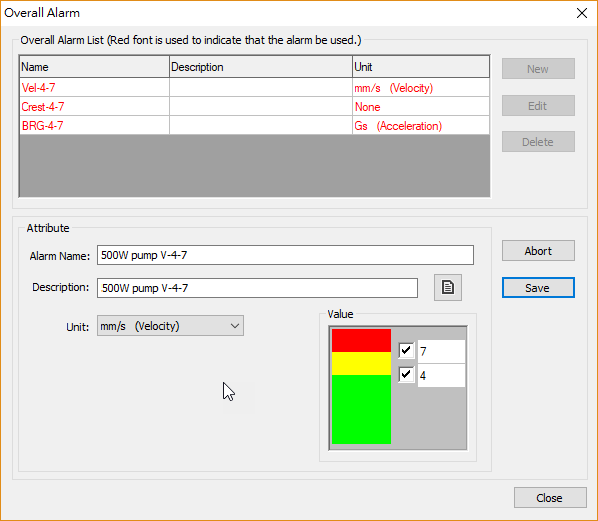

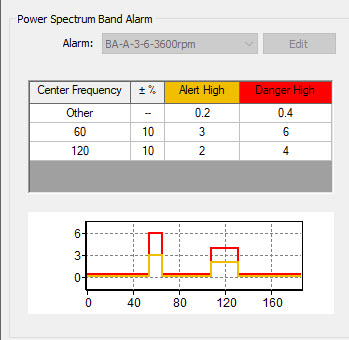

• Define the alarm status, fault frequency tables, and more.

Monitored parameters: For each monitored point, iSee Online Condition Monitoring Software allows you to select the desired vibration parameters and functions including: bearing condition values, various overall values, time waveforms, envelope spectrums, cepstrum, and up to 6 independent power spectrums.

Alarm setup and management: To create an alarm setting, first create the setting for the “alarm category.” This function is easily copied to similar machines, saving key-in time and reducing input errors. To change the alarm level, select the category level, and all associated points will be updated, saving time.

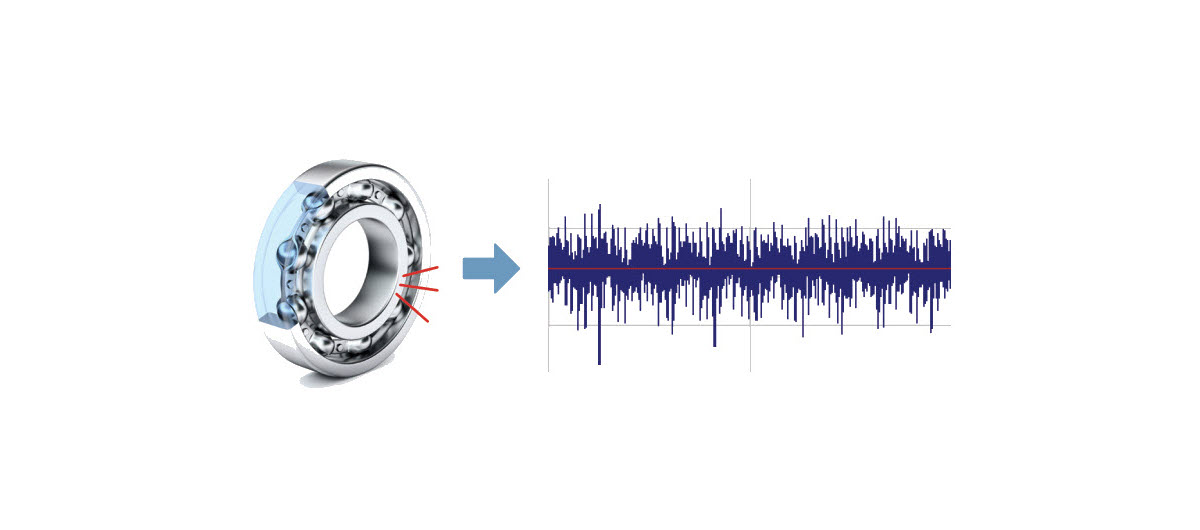

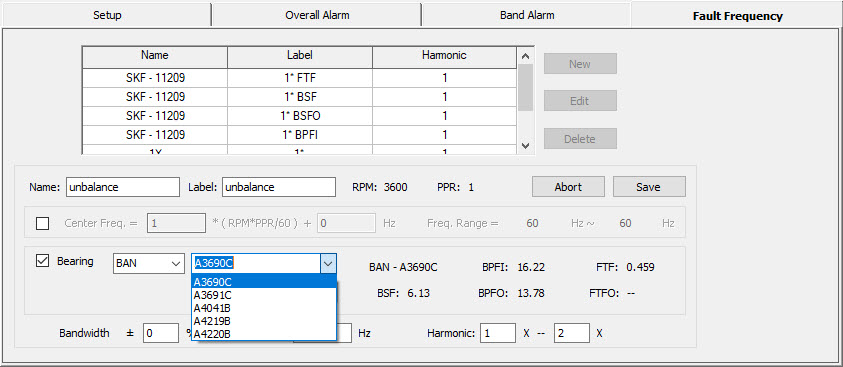

Bearing Fault Frequency Table

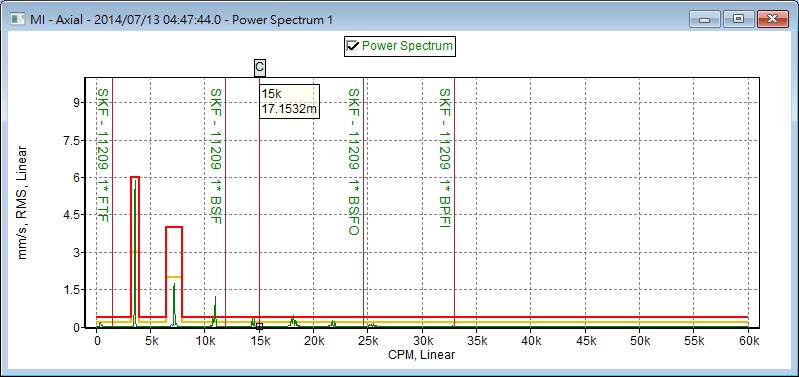

Create pre-defined fault frequencies from a database or user-entered parameters, such as multiples of the bearing rotation frequency, inner race (BPFI), cage failing frequency (FTF), and more. The bearing fault frequency display on a spectral plot makes your vibration analysis convenient and simple.When a bearing or gear begins to develop damage, the impact of the bearings’ internal components will create a vibration signal that can be viewed in iSee Online Condition Monitoring Software. This advanced machinery health monitoring software employs true-peak detection of high pass filter filtered time waveforms to properly detect this bearing fault frequencies. As damage increases, true-peak values increase. By trending true-peak values and setting correct alarm levels, critical bearings and gears can be effectively monitored.

Plot Mode

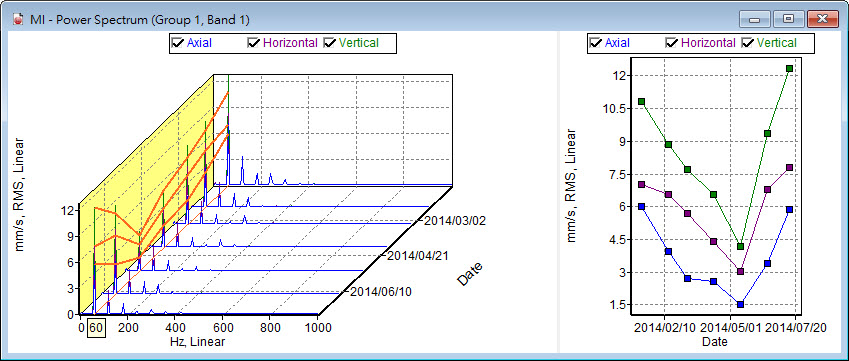

In Plot Mode, you can:• Diagnose and analyze machinery root causes.

• View live or historical spectral and time waveform plots

• Synchronize your cursor across multiple spectral or time waveform plots

• Easily view trend data.

• Enable alarm levels, fault frequencies and other diagnostic functions with a simple click of an icon, and more

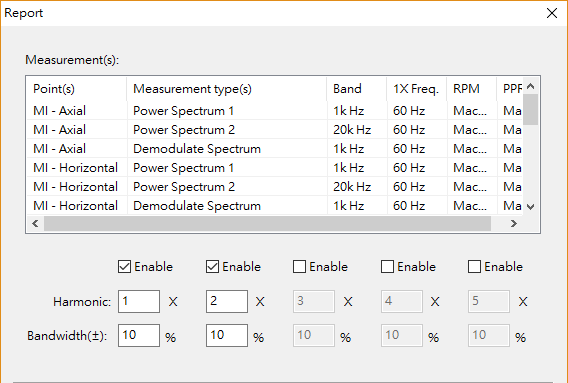

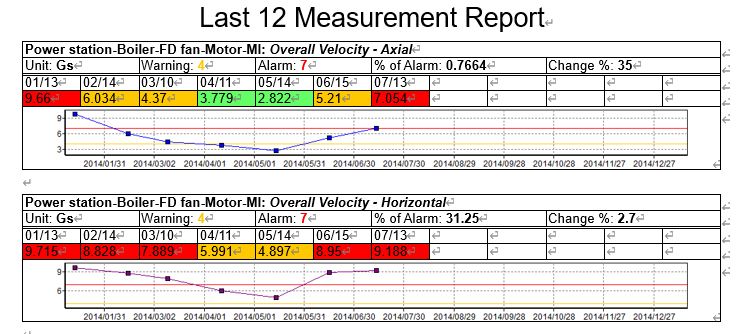

Report Mode

In Report Mode, you can:• Generate custom reports with selected formats

• Custom options with the built-in report setup wizard

Optional Servers

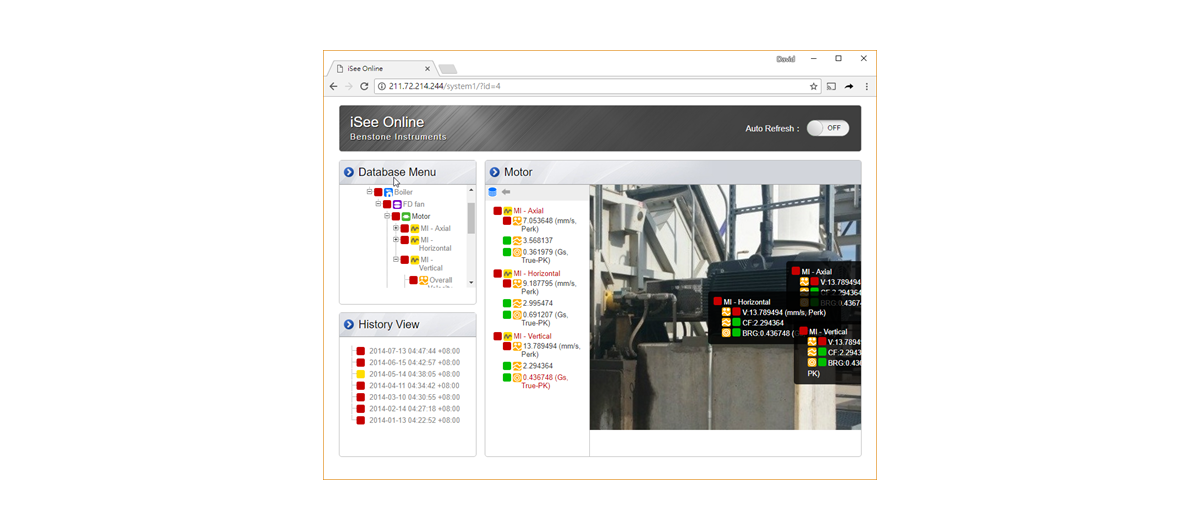

Web Server

The optional web server software allows users to view of the archive data across multiple computers and mobile devices. Unlike the traditional server/client technology, the cost-effective web server has no limitation on the number of client users, and can be accessed via all platforms- Android, iOS, Windows, or Linux. Simply log in from any browser to view the data. Additionally, the web server can be installed on a cloud network. View data over the internet, from anywhere in the world, while keeping your factory network secure.

OPC and Modbus Servers

The optional OPC and Modbus servers make it possible to share archive data at facilities that employ either an enterprise database structure (OPC) or a DCS system with a Modbus interface for further applications.

VimoNet Data Acquisition Modules

VimoNet Data Acquisition Modules are uniquely designed for easy configuration of your online condition monitoring system. VimoNet can be used, with or without a network connection, as the data acquisition front end. Alternatively, VimoNet can be deployed as a stand-a-lone data logger with relay and DC outputs. Equipped with a high-speed DSP processing chip, VimoNet can perform signal analysis and activate relay outputs, should the monitored parameters raise to alarm level in real-time.Download the iSee Online Condition Monitoring System brochure