Technology & Service

Case Study

Detecting damaged bearings of ultra-low speed machines with true-peak measurements

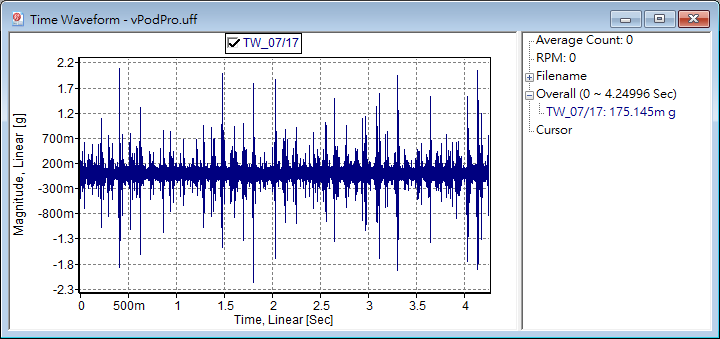

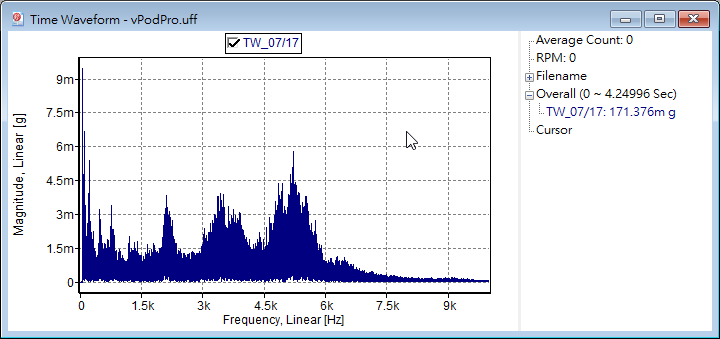

vPod Pro smart vibration meter was used to detect bad bearings successfully on ultra-low speed machines, which are rotating at around 50 rpm. With true-peak detection, vPod Pro found one of the bad bearings with 2.127g reading, and it is in red alarm condition.When examining the time waveform, periodic knocking spikes can be observed as shown on the plot below, and the power spectrum shows the bearing signal is up to 6.5 kHz, as below

It is interesting that the overall level for this signal is only 0.171 g(RMS). That means, for such low speed machines, it is not possible to detect bad bearings with conventional RMS type vibration measurements. Because the frequency of bearing signal is much higher than 1kHz, the installation of accelerometer would be very crucial too.