Products

Vibration data collectors and Analyzers

MP5 Handheld Vibration Data Collector

MP5 Handheld Vibration Analyzer

MP5 Handheld Vibration Analyzer is a compact portable 4 channel data collector that is designed for route-based data acquistion. With optional software modules, MP5 handheld vibration analyzer can conduct field balancing, ODS testing and Bump Testing as well. For measurements in harsh environments, MP5 is manufactured with a ruggedized housing by a dual injection molding process and protective sealing to provide an IP 65 rating. MP5 is equipped with a large 5-inch color (800 x 480 high resolution) touch screen. The combination of Microsoft's powerful WinCE operating system and touch screen operation provides a user friendly and intuitive interface. MP5 acquires measurement signal with precision 24-bit sigma delta AD converters to provide a high dynamic range, up to 40 kHz maximum bandwidth.

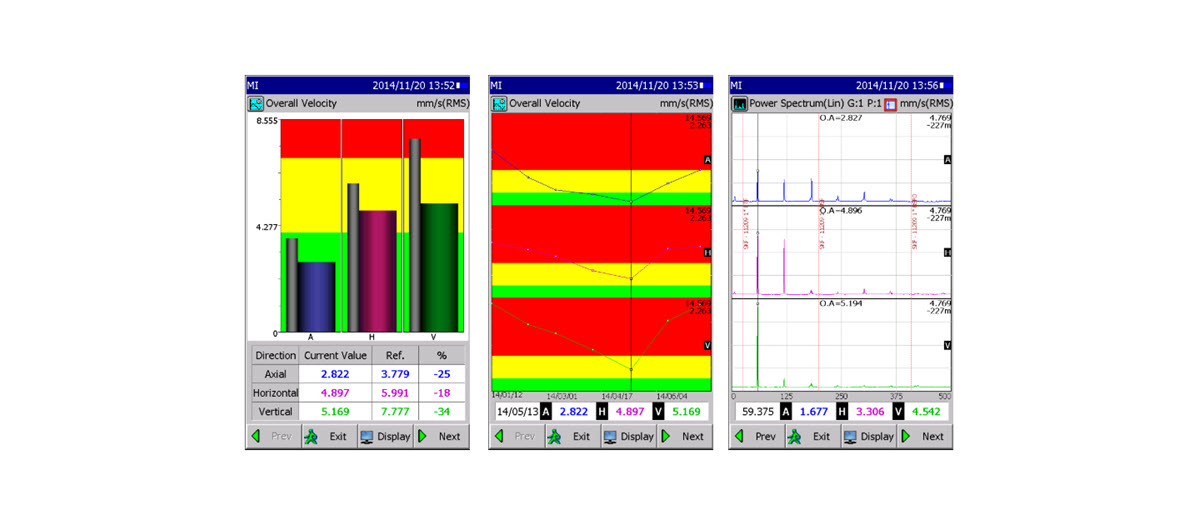

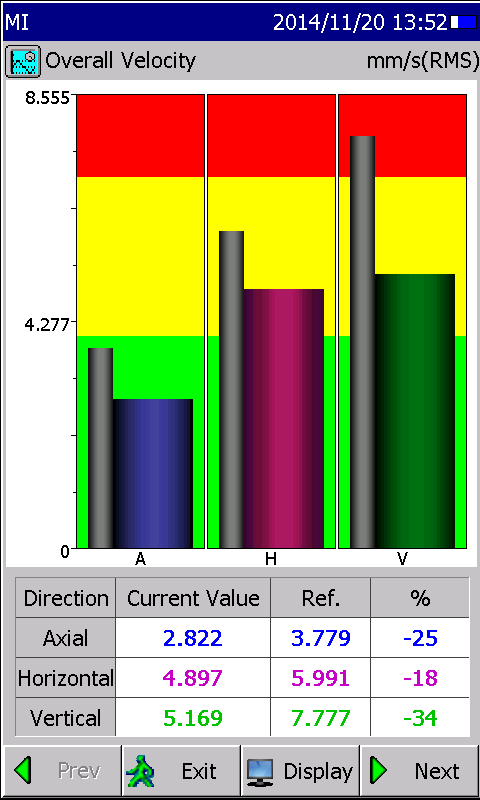

Route Based Data Collector and Portable Vibration Analyzer

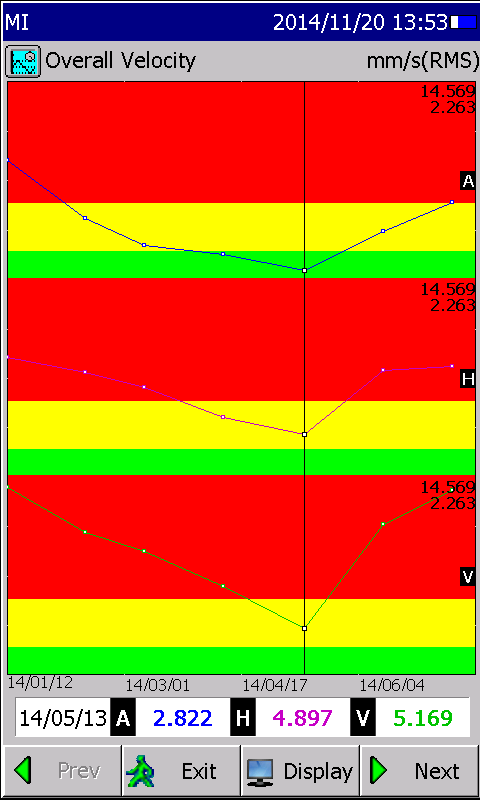

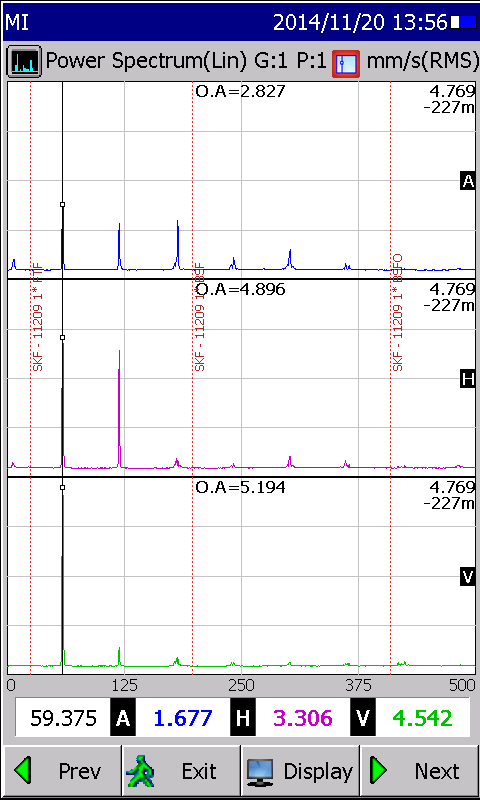

Combined with iSee, the powerful PC software built for machinery condition monitoring project, MP5 Handheld Vibration Analyzer is your best choice for route-based data acquisition. MP5 supports simultaneous tri-axial vibration measurement, saving many work hours in the field. MP5 measures bearing fault signal via true peak detection on a high-pass filtered time waveform. This field-proven portable vibration analyzer provides sensitive and accurate readings from the early stage of bearing damage, and you can track the damage development from the trending analysis feature of iSee PC software.

Envelope spectrum measurement is a standard vibration analysis feature for confirming bearing failure. Temperature and other process parameter measurements are also supported by this handheld vibration analyzer.

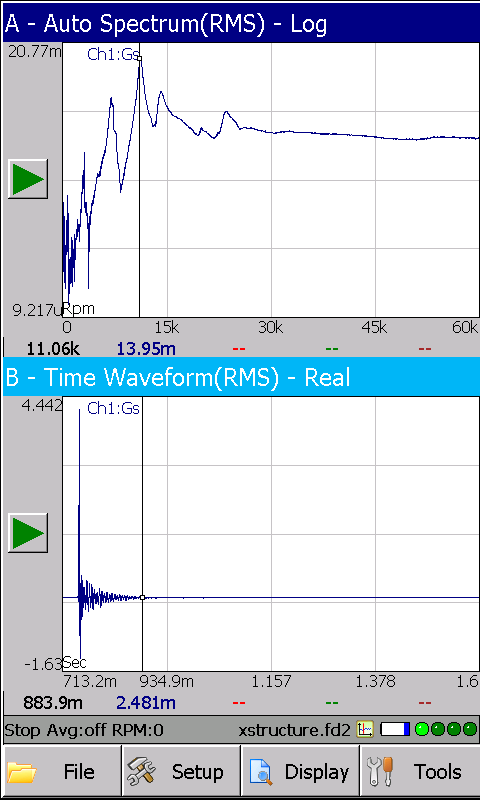

Bump Test Module

MP5 Handheld Vibration Analyzer's powerful Bump Test module allows you to conduct bump test on a structure and measure its FRF, coherence, and cross power spectrum functions. This useful module helps you to investigate the resonance of a machine, conduct structural reinforcement and reduce the vibration level of a machine running at resonance zone. The test data can be imported to a 3rd party software, like ME’Scope, for further modal analysis to derive its modal shapes, natural frequencies and damping values.

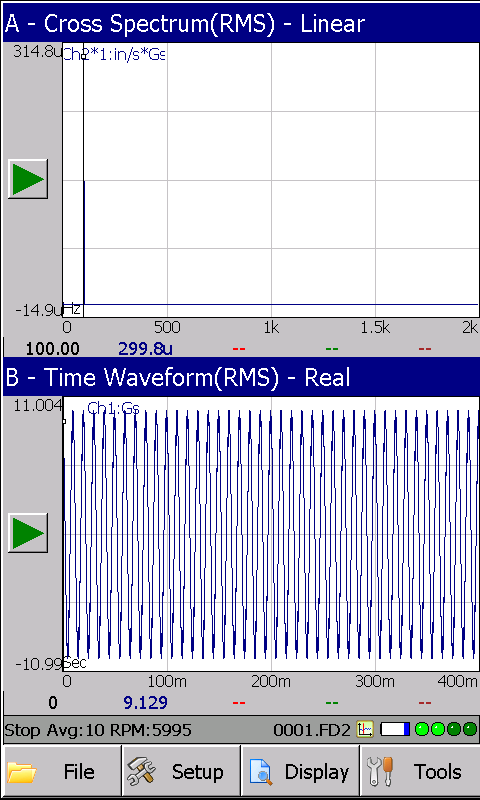

ODS Test module

MP5 Handheld Vibration Analyzer's ODS Test module allows you to conduct ODS test on a running machine and measure its FRF, coherence, and cross power spectrum functions. With the reference vibration sensor connected to channel 1, and a triaxial vibration sensor connected to channel 2, 3 and 4, MP5 saves your time for the measuring tasks in the field via real-time four channel measurements. By importing the test data to a 3rd party software, like ME’Scope, you may derive the Operational Deflection Shapes of your machines easily. The ODS test helps to find out how the structure deflects at certain running speed, provide useful information for structural reinforcement.

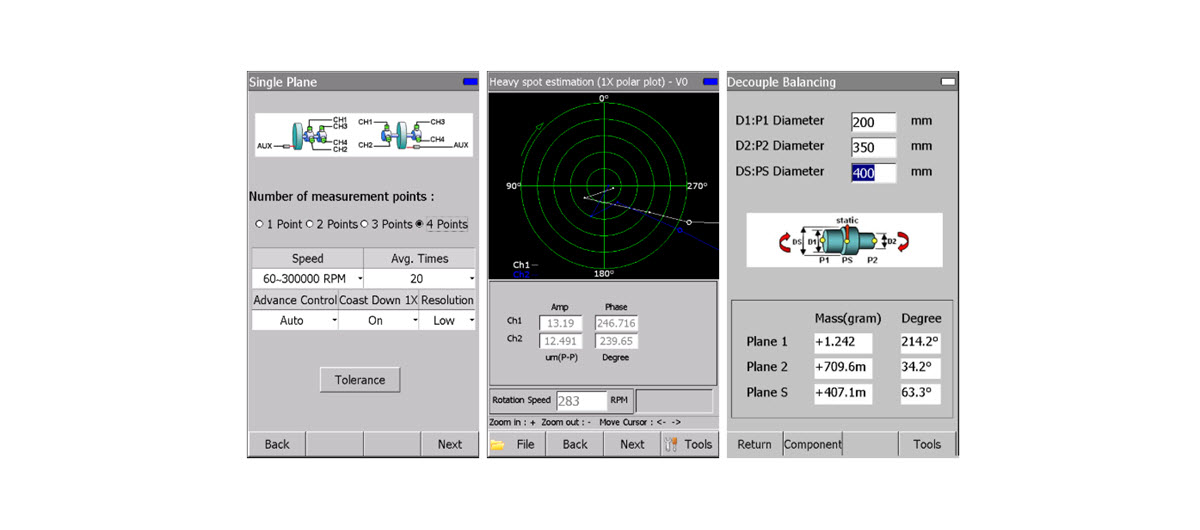

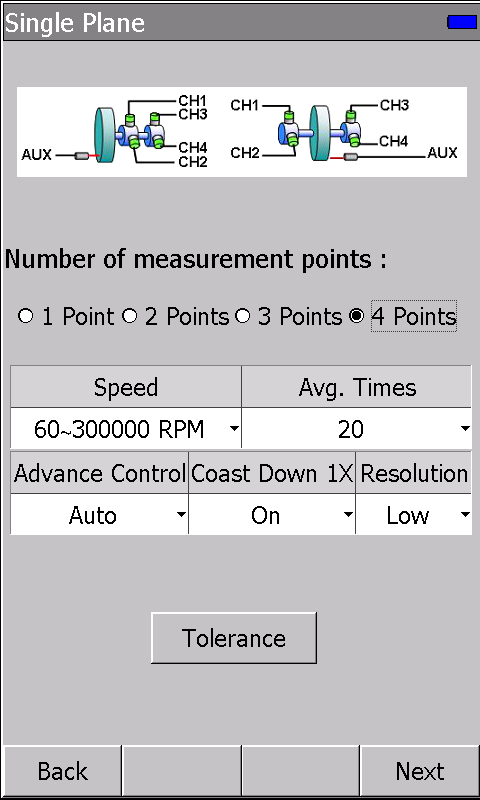

Field Rotor Balancing

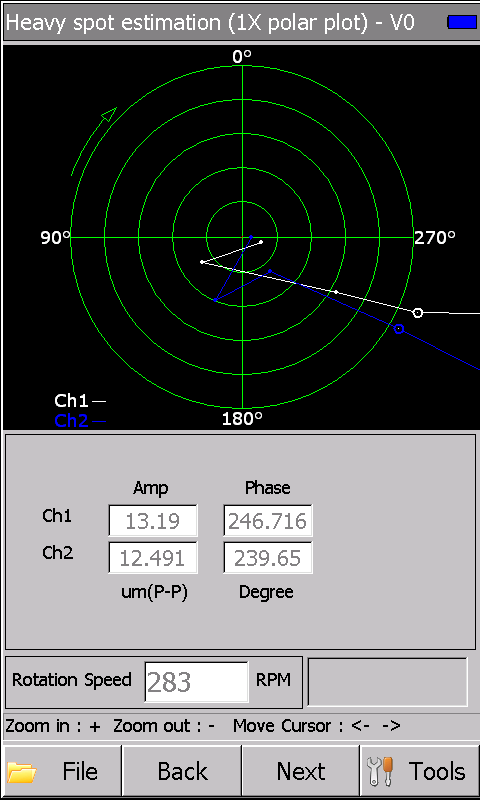

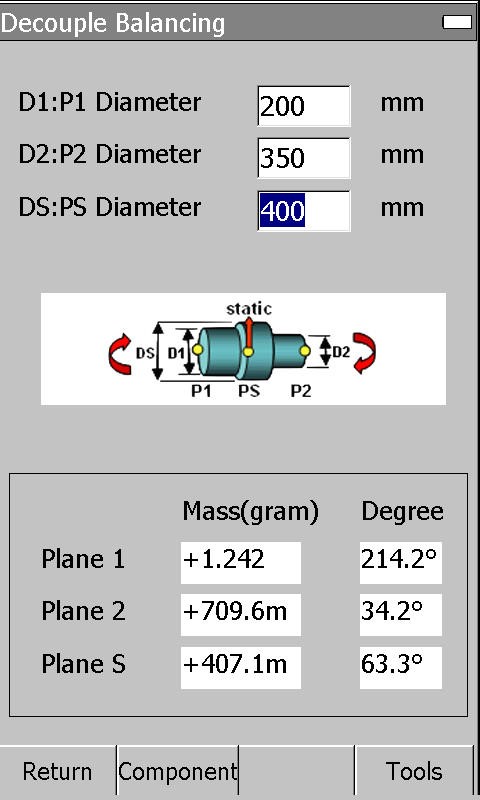

The MP5 portable vibration analyzer with the (optional) balancing software package can balance your rotating machines in the field with industry leading balancing techniques like; single plane, dual plane, overhung dual plane, 3 plane, 4 plane and 3 weights balancing. This advanced balancing software makes it very simple to balance machines in the field with a very high level of accuracy. Now with multiple-point balancing, vibration in BOTH horizontal and vertical directions are minimized at the same time. By enabling coast-down measurements for 1X vibration, the heavy spot is identified correctly with only one measurement, saving you time, money and increasing safety. This technique prevents the user from danger by putting the trial weights in the wrong place and shortens the time required for rotor balancing. Other rotor balancing features / functions are:

● Multi-point balancing● Component calculation

● Drill depth calculation

● Allowable residual unbalance calculated from the ISO 1940 standard

● Unequal radii calculation

● Decoupled balancing (couple + static)

● Review historical vibration data on a polar plot.

● Review historical balancing data on a polar plot

● Heavy spot estimation with one shot measurement.

● Redo a previous balancing job with saved balancing factors.

● Continue an unfinished balancing job from a saved file